COWELL® IMPLANT SYSTEM

INNO Submerged Implant

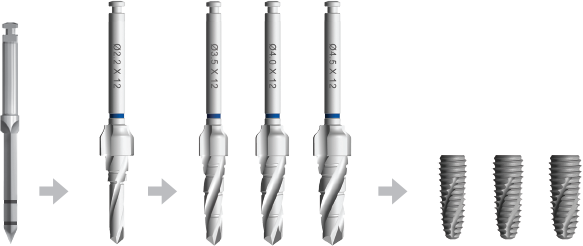

System Flow

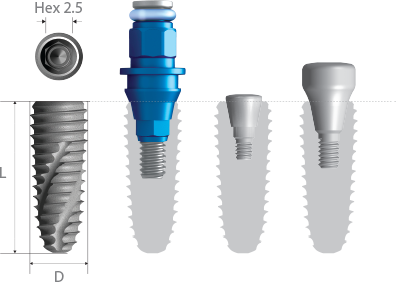

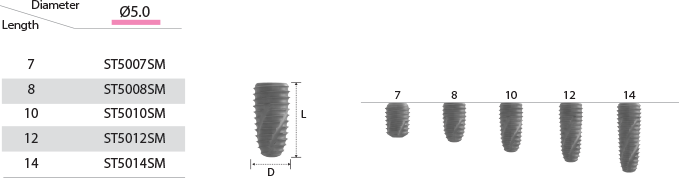

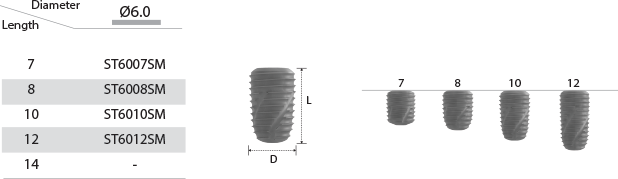

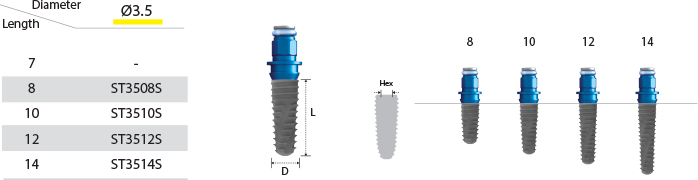

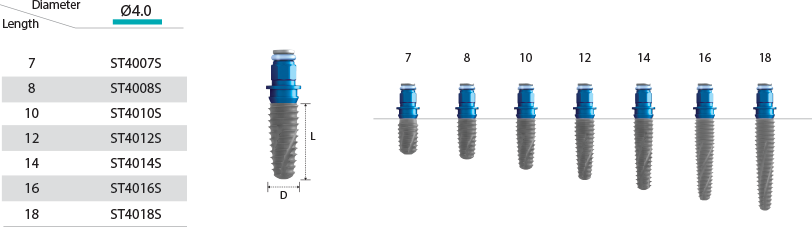

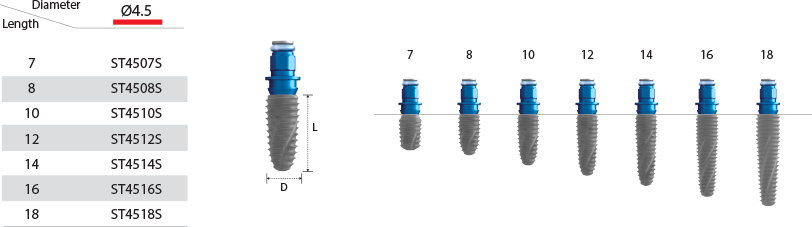

Submerged Fixture

Submerged Fixture

Surface Treatment : SLA-SH®

- Interchangeable with hexagonal morse tapered fixture.

- Internal hex connection (Taper 11°/ Hex 2.5).

No-Mount

- Packing Unit : 1 Fixture + 1 Cover Screw

Pre-Mount

- Packing Unit : 1 Fixture + 1 Cover Screw + 1 Mount

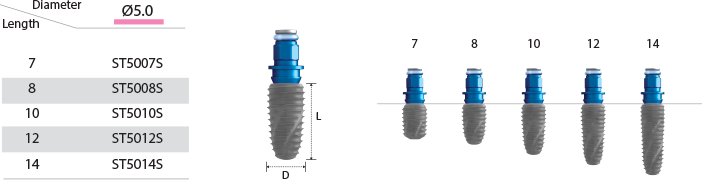

INNO SUB. FULL SURGICAL KIT

[KCA010F]

- For INNO Submerged Implant System (Sub.).

- All components are for Sub. / Int. / Ext. except for the Fixture Drivers and the Depth Gauge used for Sub. exclusively.

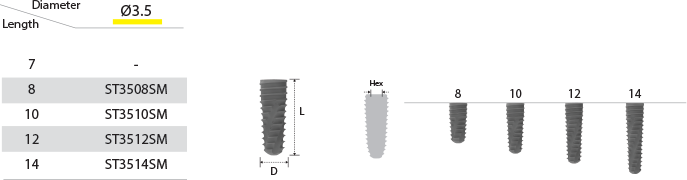

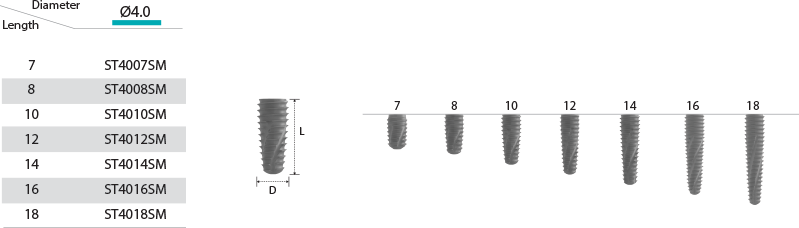

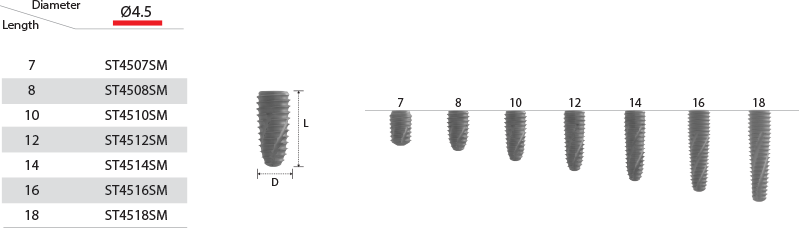

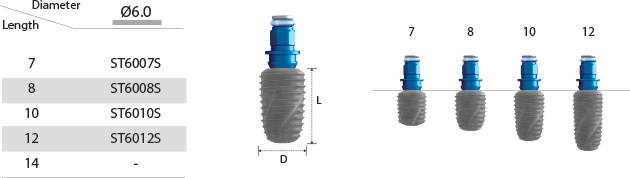

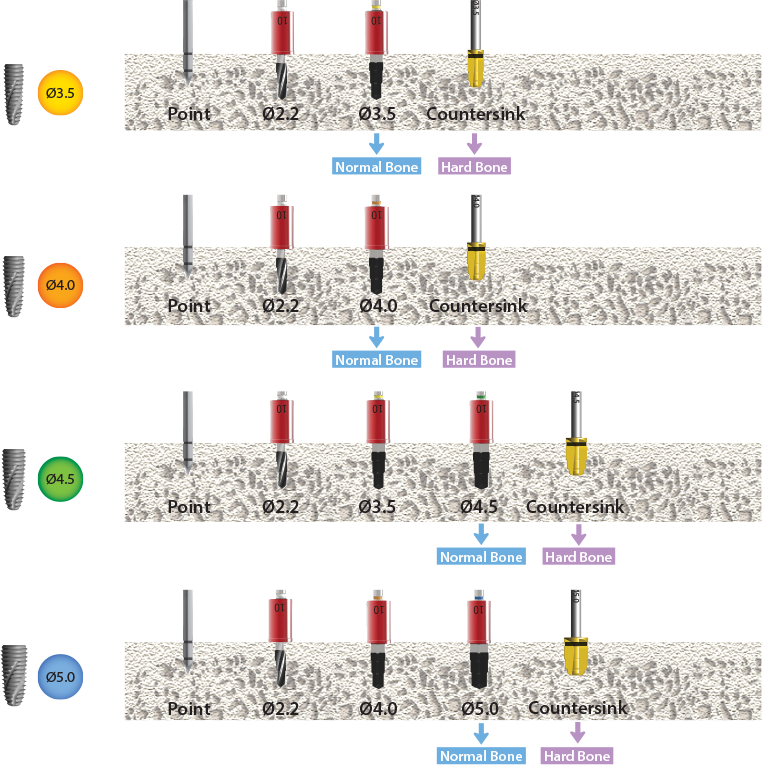

Drilling Sequence E.g. 12mm Fixture

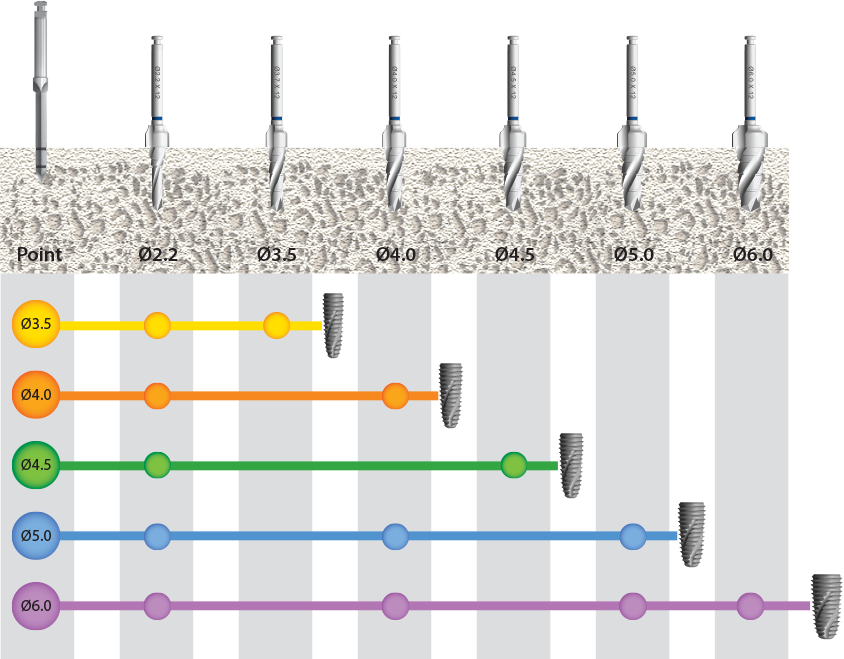

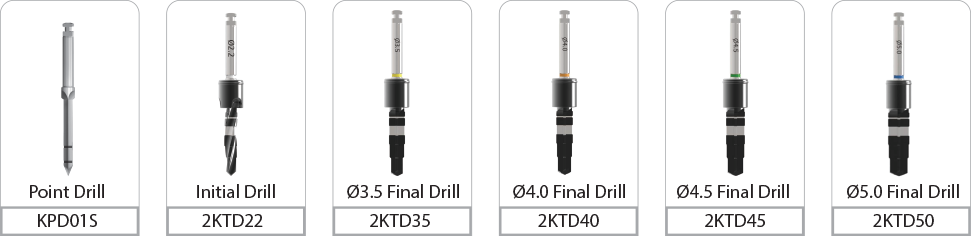

- Minimal drill frequency with the Point Drill, Initial Drill and Final Drills

(Ø3.5, Ø4.0 and Ø4.5 Fixtures).

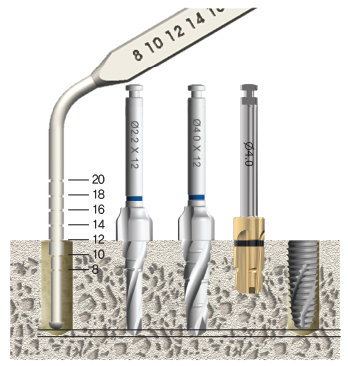

- Length Marking

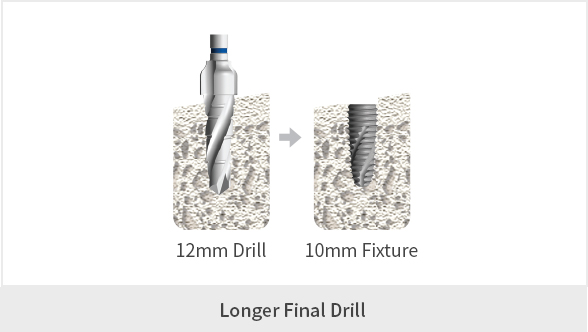

Actual length of Drill : Fixture + 1mm

- Ø5.0 fixture : a series of the Point Drill, Initial Drill, Ø4.0 Final Drill and Ø5.0 Final Drill.

- Ø6.0 fixture : a series of the Point Drill, Initial Drill, Ø4.0 Final Drill, Ø5.0 Final Drill and Ø6.0 Final Drill.

※ The Countersink and Tap Drill are used in hard bone quality.

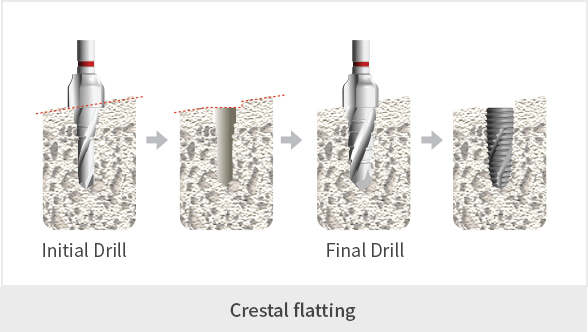

※ Sloped edentulous ridge adjacent of tooth

- Crestal cutter of the Initial Drill and Final Drill.

- Longer drills than fixture’s length.

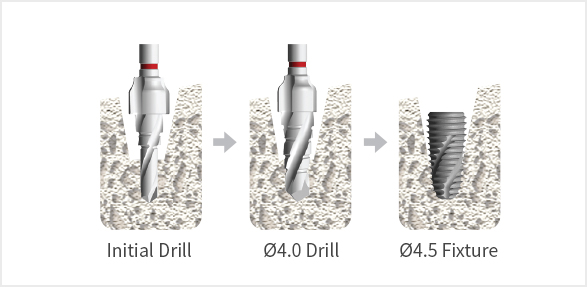

※ Wide extraction socket

- Absence of the cortical bone & spongy bone.

- Narrower diameter than the fixture’s diameter.

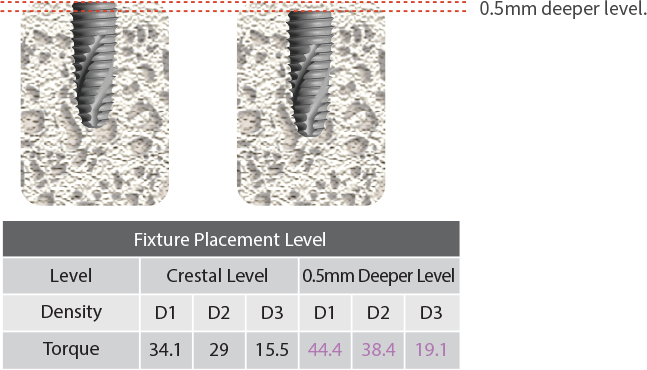

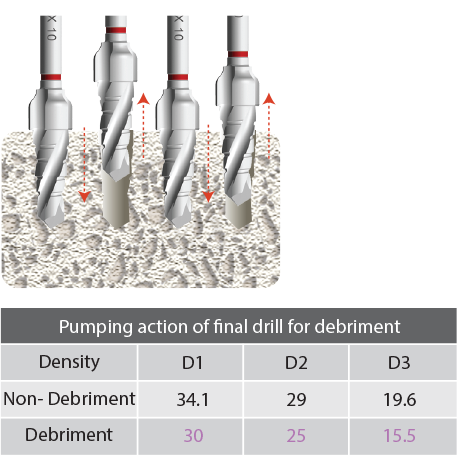

※ Torque force control

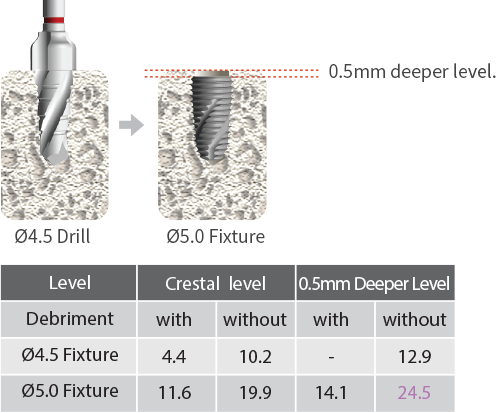

- The 0.5mm deeper placement increases the initial torque force of fixture.

- The pumping action of drill removes the bone chip in the hole.

- In dense bone, the debriment action decreases the high torque force.

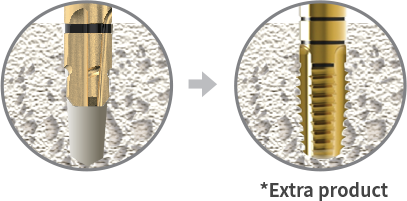

※ In weak bone quality 4 of maxillary tuberosity

- No pumping action.

- 0.5mm deeper placement of fixture.

- Wider fixture than Final Drill.

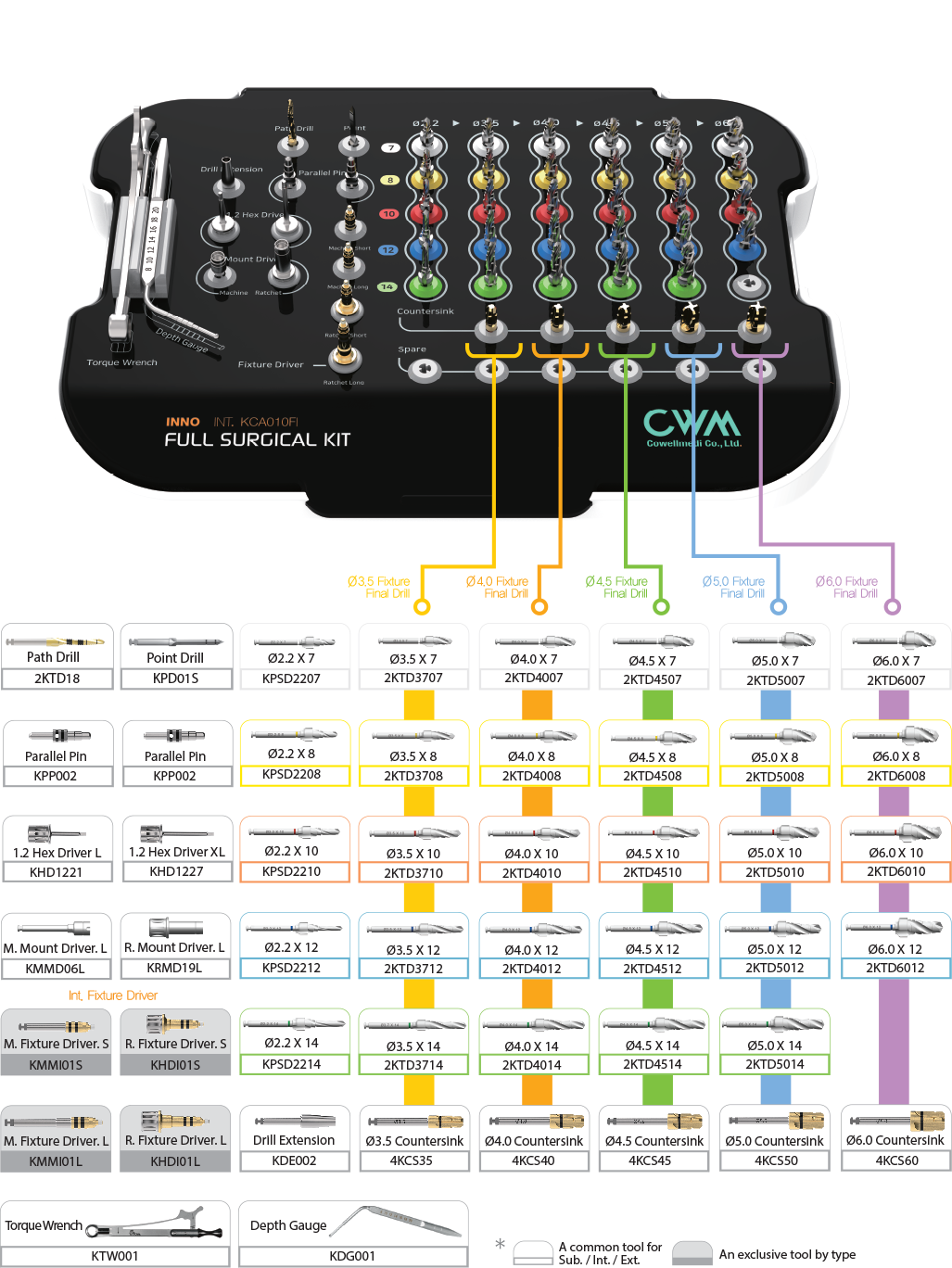

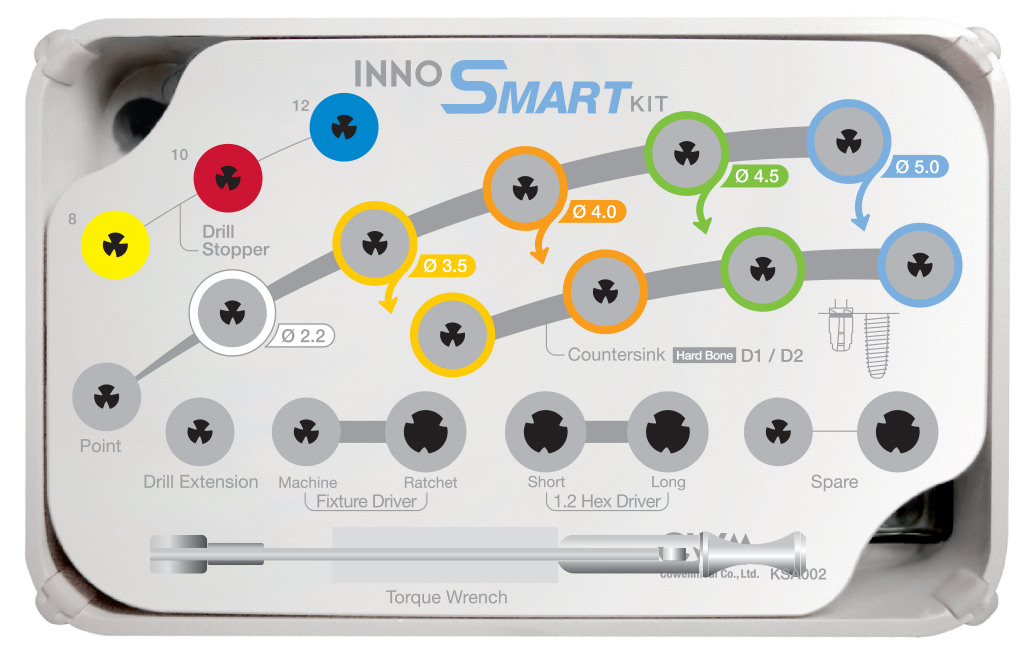

INNO SUB. SMART SURGICAL KIT

[KSA002]

- For the INNO Submerged Implant System (Sub. Ø3.5, 4.0, 4.5 & 5.0).

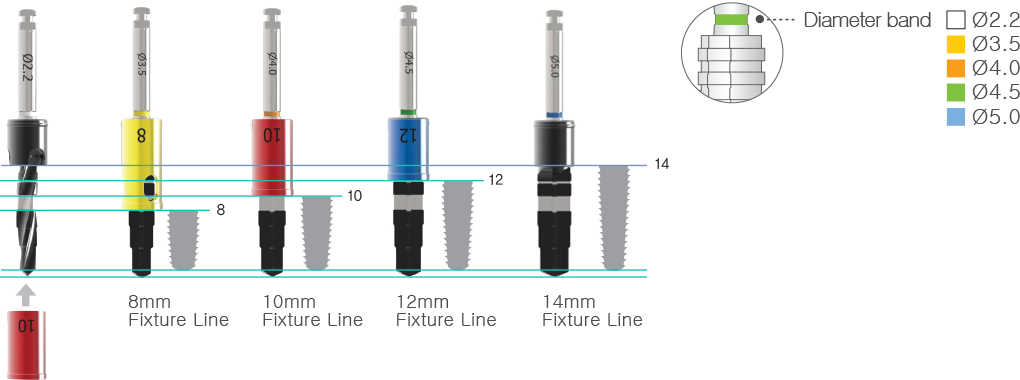

- A simpler kit for implant surgery, applied to fixtures with 8~14mm in length using the Drills and Stoppers.

Drill

Stopper

Countersink

Extension & Driver

Length Marking & Stopper

Actual Length of Drill : Fixture length + 1mm.

* While the 2.2 Initial Drill is used at 1,000 rpm with irrigation,

the Final Drills from the 3.5 to 5.0 should be used at 50 rpm without irrigation.

Drilling Sequence

THE PRODUCTS CATALOG OF COWELLMEDI